TRACKS FEATURES

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

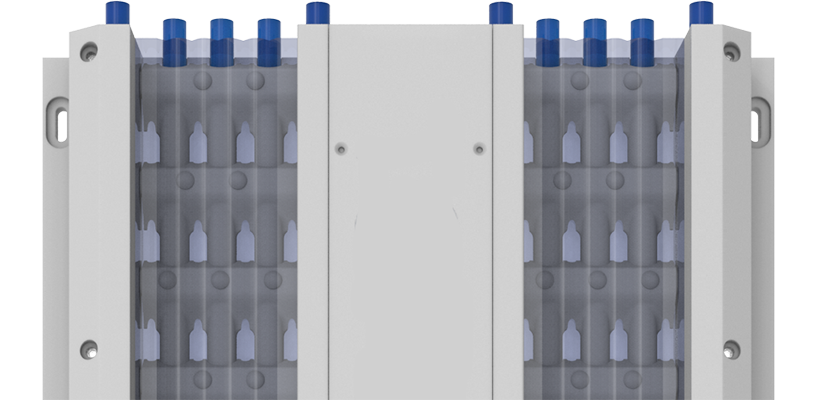

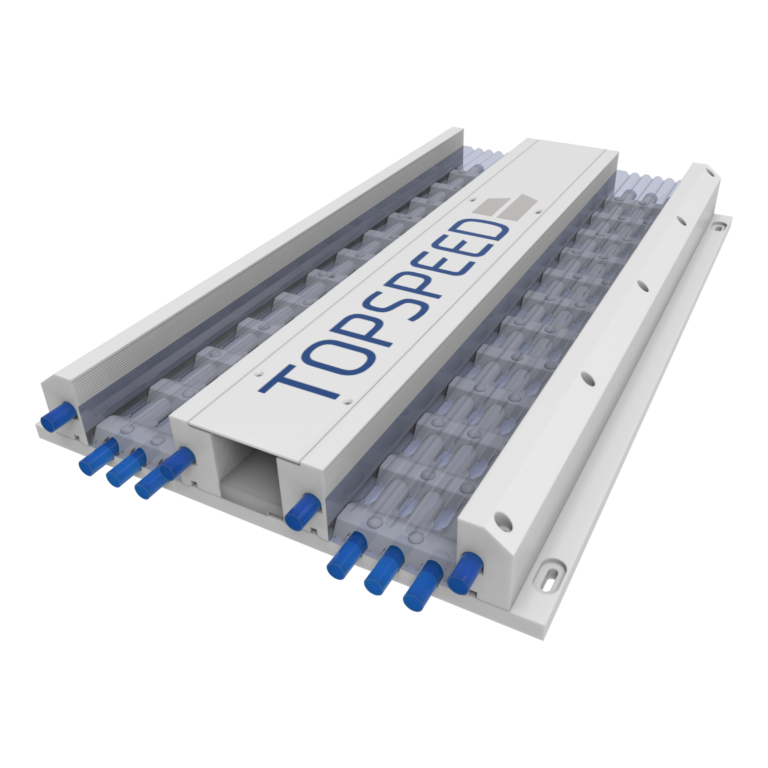

Direct cooling - Direct contact between the cooling pipes and the ice mixture reduces energy costs and increases cooling efficiency.

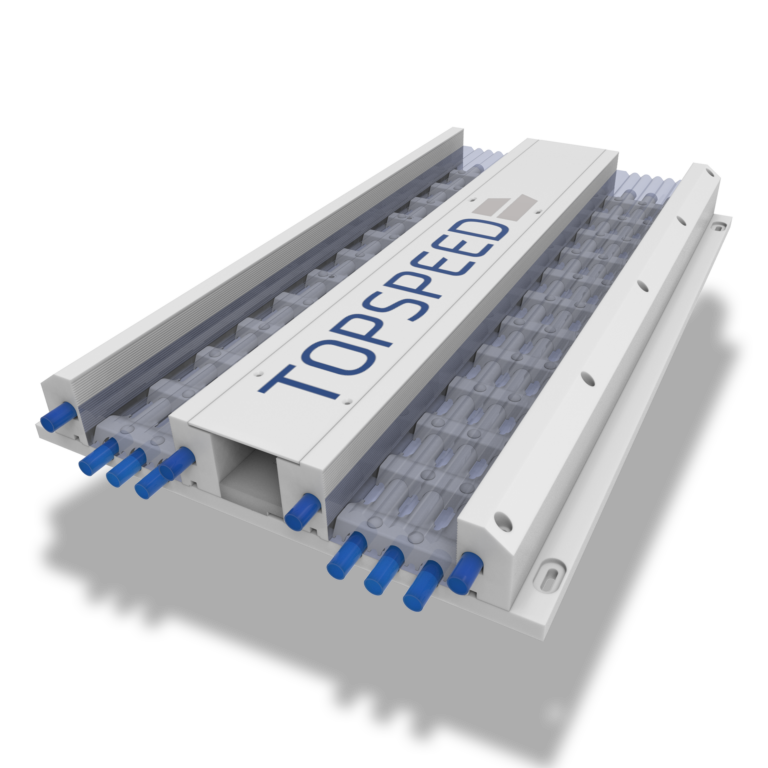

Middle plate design - Our middle plate design enables the ability to easily install a camera in the middle of the track. Integration of TopSpeed Illumination System is possible.

Modular composition - Quick and easy on-site replacement of damaged elements.

Sliding channels - No additional adjustment is needed between winter and summer.

Incorporated leveling system - The incorporated leveling system allows us to install the in-run track on uneven surfaces.

Cooled edges - The only in-run track with 3-side cooling

Other features

Time efficient

- Fast preparation of the in-run track

- Extension of winter season

- Intuitive and easy to use cooling device

- Fast migration from winter to summer use of track

Cost efficient

- Low manpower needed

- All-in-one summer and winter in-run track

- Low maintenance and operational cost

- Low energy consumption

- Low water consumption

- Regulation of snow temperatures

- No installation of extra rail for ice tiller/mill needed

Exclusive features

- Cooled edges

- Direct cooling of snow

- Simple preparation of ice track at temperatures up to +10°

- Small variance in ski jumpers’ speed (equal conditions for all jumpers)

- Use of ironing device for track preparation

- Two cooling compressors which acts as a back-up system

Certificates

- FIS Certified

- CE Certified

- Patented technology

- Registered brand name

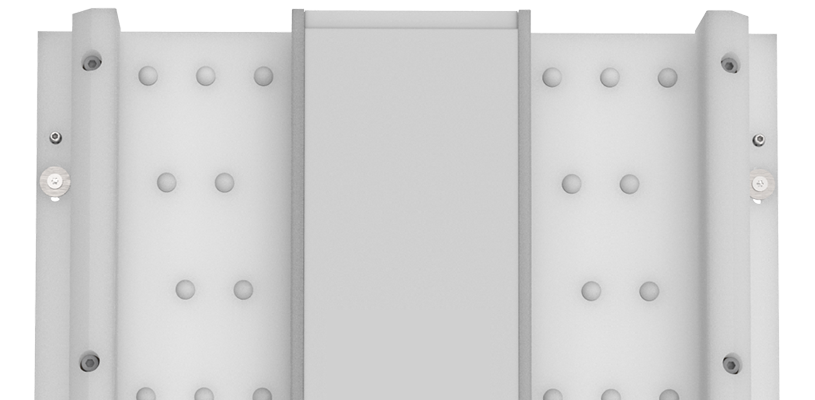

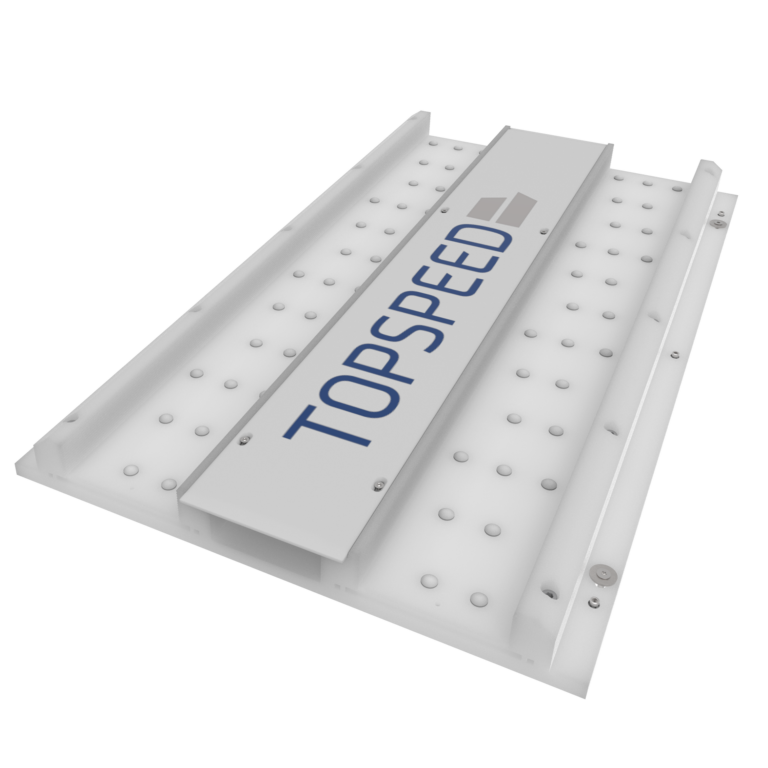

Asymmetric position of ceramic knobs helps to reduce friction between the skis and the ceramic knob.

Middle plate design - Our middle plate design enables the ability to easily install a camera in the middle of the track. Integration of TopSpeed Illumination System is possible.

Modular composition - Quick and easy on-site replacement of damaged elements.

Materials that are used contain UV stabilisers and additives that increase slickness for greater slide.

Compatible leveling system - Compatible with both TopSpeed® leveling systems.

Sprinkling system - A centrally positioned sprinkling system ensures optimal moisture conditions on the tops of the ceramic knobs.

Other features

Time efficient

- Fast preparation of the in-run track

- Fast conservation of track for the winter season

Cost efficient

- Low manpower needed

- Low maintenance and operational cost

- Low water consumption

Exclusive features

- Small variance in ski jumpers’ speed (equal conditions for all jumpers)

Certificates

- FIS Certified

- CE Certified

- Patented technology

- Registered brand name