TopSpeed’s® team of experts will go an extra mile with you and make sure you are all set to use our products to their full extent. Our design team will offer you the best solutions for renovation or plans for the new hill, provide you with technical details and provide guidelines for a local construction company.

Since all technical design is done in-house you get a guarantee that all solutions provided by us will fit together perfectly, especially when assembled by our installation team. Maintenance of top-end products is a must, and we provide it as well. When the most important competition comes, we can support you with our competition supervision team.

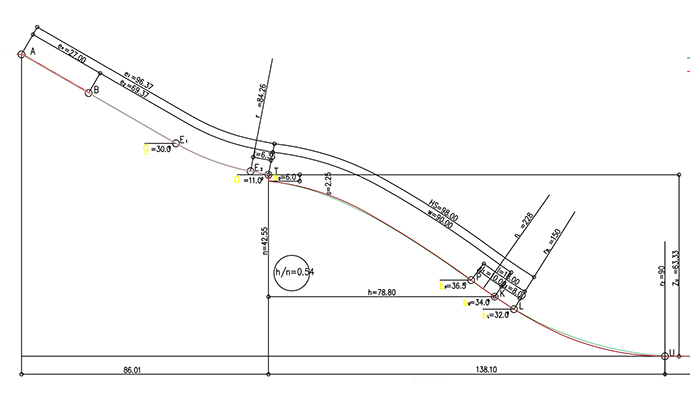

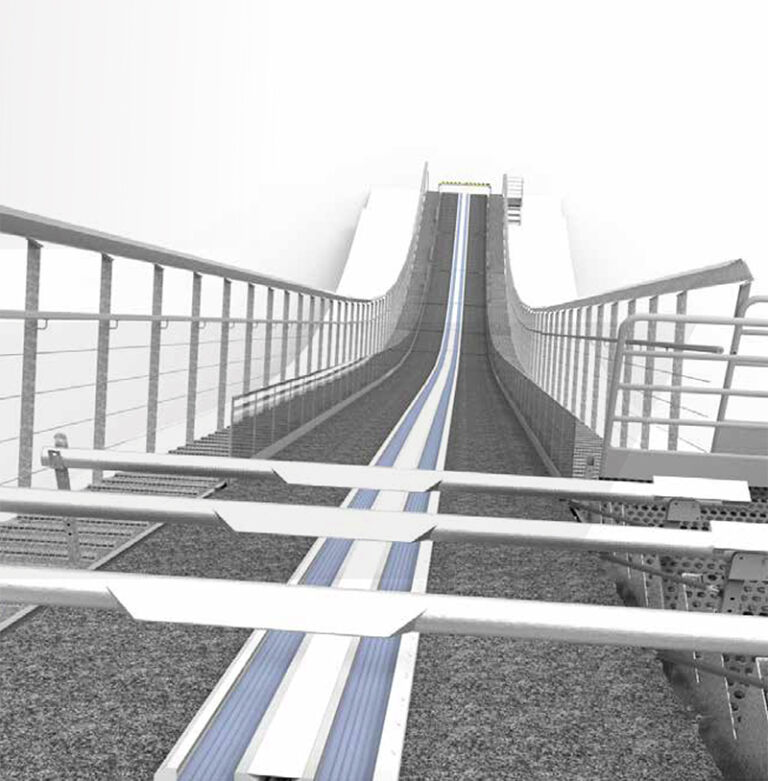

Profiles of ski-jumping hills must be constructed in compliance with FIS norms, and the federation heavily scrutinizes their implementation. The design of a ski-jumping hill can still exhibit a certain degree of freedom with respect to adjusting the profile to local geological, climate, or other specific conditions.

The planning of a new ski-jumping hill and conversion of an outdated existing one both require the design of a new profile. Designing a profile for a new ski-jumping hill means more freedom (no legacy work) but also more responsibility – there are many various factors that must be considered during this phase.

Redesigning a profile is usually part of a larger renovation plan with many variables that must be taken into account, such as the current profile line, existing infrastructure, and requirements and wishes of the customer. Obtaining comprehensive and exhaustive information about the current status of the ski-jumping hill is the key to a successful implementation of our redesigned profile.

TopSpeed® Profile Design includes: ski-jumping hill technical parameters; positioning the profile into an orthophoto model (geographical model of the land provided by the investor); bird’s-eye view of the jumping hill; horizontal and vertical profiles of the ski-jumping hill; calculation of the excavation and utilization of excavated excess soil; analysis of possible locations for the coaches stand and judges tower.

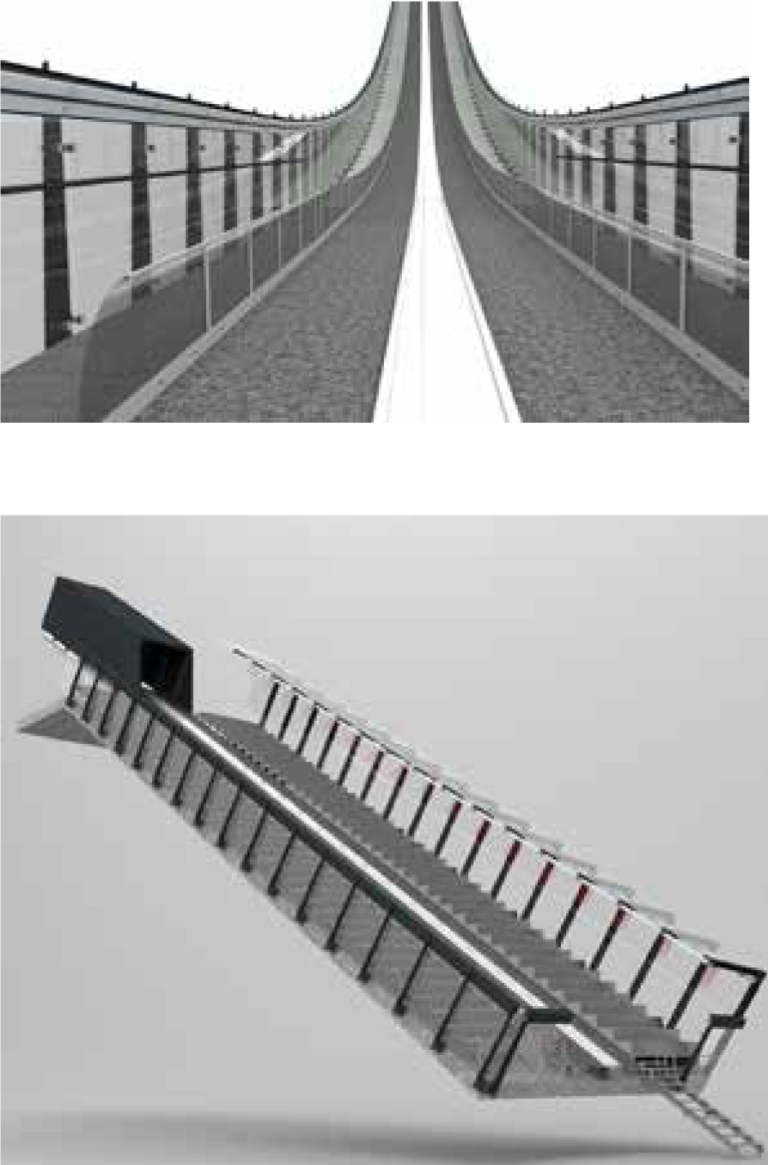

Once the main architectural design is complete, the preparation of the technical design can begin. Every detail of the ski-jumping hill is specified in this design. It foresees all specifics of the custom made solution and includes detailed production and installation plans.

TOPSPEED® TECHNICAL DESIGN INCLUDES THE FOLLOWING STEPS:

3D MODELS: 3D presentation of the entire facility including all auxiliary buildings to check compliance with architectural design

SIMULATIONS: before installation, we perform the following tests for every part of our technical design:

• Wind load simulation (if necessary)

• Construction load calculations

• Strength calculations for construction elements

• Calculation of cooling system performance depending on the jumping hill position

• Calculation of pressure drops in the cooling system

• Preparation of lighting design simulation

WORKSHOP DRAWINGS: comprehensive drawings for a single element, which enables error-free and time efficient production

WORKING SCHEMES: technological schemes of operation are prepared for TopSpeed® Cooling System, TopSpeed® Sprinkler System, TopSpeed® In-Run Track Lights, TopSpeed® Illumination System, TopSpeed® Ice Cutter, TopSpeed® Cover System, and other systems supplied by TopSpeed®

INSTALLATION PLANS: installation manual for our installation team to speed up the installation process and minimize the possibility

of mistakes. The installation time schedule is also part of the installation plans

The installation process is one of the most important steps in the construction of a ski jumping hill. TopSpeed® has a highly experienced installation team where every team member is in charge of specific tasks. Our installation team consists of specialists from various specialty fields (construction engineers, electrical engineers, plumbers, mechanics, land surveyors, and high altitude workers). All members of the TopSpeed® Installation team have many years of experience in the field and are included in our company’s internal training program.

An accurate installation plan, prepared at TopSpeed® headquarters, is crucial for the high quality, safe and fast installation work we provide. Weather conditions can, however, affect the timeline of the installation, but we are able to adjust our plans quickly and effectively, so this does not have a serious impact on the installation completion date. The most important element that ensures smooth TopSpeed® Installation is the proper preparation of the construction site in accordance with our requirements. We prepare these and send them to the investor prior to our arrival.

MAINTENANCE

TopSpeed® technical equipment must be maintained regularly to assure best performance and long lifetime.

To make it as simple as possible, TopSpeed® offers long-term maintenance support of supplied technical equipment. Our service includes maintenance and keeping of service records, and we also monitor service cycles of all installed systems. The costs of maintenance can be reduced by concluding a long-term maintenance contract. In this case, TopSpeed® will make sure that your systems are maintained at the right time to ensure optimal performance of your equipment.

In case of urgency due to an upcoming event or unexpected damage to the system, our team of experts is always available to provide the best possible support.

If you have a strong local support and maintenance team, TopSpeed® can provide training for the supplied technical equipment so they can perform these tasks themselves. The specified warranty period is only valid if the systems are regularly maintained.

Knowledge transfer is one of the final steps in the construction or renovation of a ski jumping hill venue. The TopSpeed® team is always present on site during the first preparation of a TopSpeed® In-Run Track for winter conditions. At that time, our experts transfer to the local team all of the required knowledge about the operation and daily maintenance of installed TopSpeed® systems. Training usually lasts two days and includes detailed explanations about the functioning and operation of the installed systems.

TopSpeed® Training covers: cooling system control; snow mixture preparation; filling of in-run track channels with snow; ice cutting procedure; covering and uncovering of the in-run track; using the sprinkler and irrigation systems and preparing them for winter; lighting and illumination systems control; assembly and disassembly of snow retention nets.

There is no room for mistakes in the organization of competitions on the highest level. Everything must be prepared and maintained perfectly for the event to run smoothly.

Topspeed® Competition Supervision offers a complete service – from the preparation of the in-run track and other Topspeed® systems to supervision during the competition.

For FIS competitions, the distance between the ice surface and the in-run track edge must comply with FIS rules. To ensure this, the TopSpeed® team arrives at the ski jumping venue several days before the event. We coordinate with the local team to prepare the best ice-track and make sure it is properly maintained until the time of the competition. Owing to our considerable experience, we can ensure that the TopSpeed® Cooling System is set perfectly in accordance with the outside temperature. If anything goes wrong, our team always has critical spare parts on hand and can solve any problem quickly and effectively.

When it comes to the most important competitions of the season, it is important that LOC members have one worry less.